Sometime near the end of Summer, beginning of Fall I had the delightful opportunity to meet with AJ Wentworth who is the owner, founder, chief chocolatier, and jefe of The Chocolate Conspiracy located in Salt Lake City, UT (900 S 265 E Salt Lake City, UT 84111, to be exact). I had a great time interviewing AJ and learned a lot about his business and what it takes to specialize in the raw chocolate business. Unfortunately because of website issues, I was unable to post the interview until now.

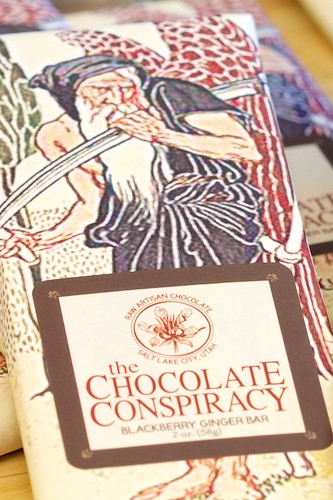

But the story begins before the interview. I met AJ at the 2013 Honey Bee Festival in Salt Lake City where two things brought my attention to his booth: 1) free chocolate samples (obvious attention grabber there), and 2) the really cool throwback art on the chocolate bars, and 3) it was RAW chocolate. My curiosity was peaked. Apparently I’m a sucker for raw gourmet chocolate wrapped in retro Asian-inspired art.

After a few months passed, I decided to take my family on a homeschool field-trip to AJ’s chocolate shop so they could see see how chocolate is made and perhaps peak their interest in entrepreneurship. AJ was very pleasant and had a lot of fascinating things to say during that visit, things that I thought were worth sharing with all of you. Naturally the next thing to do was set an appointment and pick his brain. So here we are. Enjoy!

A special thanks to AJ for his time, and also to CastingWords for their transcription services.

Listen to the Interview

Total Listening Time: 55 minutes

Read the Interview

Note, this is a word-for-word transcription of the interview. I’ve gone through and edited it slightly, but expect a few fillers now and then. If you’d rather not read the full interview, I’ve gone through and bolded parts that I thought you’d find the most interesting for a quick read. I’ve also scattered a few pictures of his shop and products throughout the interview (so make sure you scroll to the end).

Full Read Time: 15-20 minutes

Bolded Read Time: 5 minutes

I went to this place in Arizona, called the Tree of Life. It’s a rejuvenation center, and the focus was diabetic healing, cancer healing, MS healing, general detox, relieving stagnation of the liver, cleansing the kidneys, the colon, things like that.

I did an apprenticeship down there for quite a few months learning how to prepare food a certain way that didn’t have any animal products. All the products were vegan friendly, and another aspect to it was that nothing was heated or cooked. The whole philosophy that if you cook or heat any of your products or your food, you’ll lose enzymes, nutritional value, vitamins, minerals, things like that. When I was down there—this was quite a few years ago, 2007—I was introduced to a raw cocoa bean. Someone handed me a little chocolate bean, and I had never seen chocolate in that form.

It just sparked my mind a little bit as far as what chocolate’s role is in the health community and as a food. What is this food? Where does this come from? I had some other experiences where I worked. After I left the Tree of Life, I worked on an organic farm, and I worked at the rejuvenation center, again, up north of Seattle.

I was just able to have a good experience with food and with people, and learning about where it came from as far as producing it and making it as fresh as possible. I was always fascinated with nutrition. I ended up studying nutrition. I went to a school out in New York City, and as I was finishing my certification, I started playing with chocolate a lot.

The concept I wanted to do was design a healthy desert shop. The main idea was to evolve the business into a healthy place where people can come and get a cheesecake for breakfast or, and I actually…

[laughter]

I grew up in Utah. It just was a smart move to come back this direction and everyone’s like, “Why are you here”? Like, “Why’d you come back to Salt Lake? Your business would do so much better in California or New York.” I’m like, “Yeah, but there’s already business like this in California and New York. There’s nothing like this in Salt Lake for what I do.”

There’s lots of chocolate. Salt Lake has a rich, amazing chocolate scene, but they don’t have a raw chocolate scene. That was really my concept for coming back to Salt Lake and starting a business.

If you want to make syrup you’ve got to process it. If you want coconut sugar you’ve got to process it. Even agave, you’ve got to process it. That was my main concept for doing honey, is that it’s the only natural inherent sweetener that can be found in nature.

Also, we’re not processing the cacao. I feel like it’s in its more natural state anyway. So the difference with the chocolate itself is the beans haven’t been roasted or heat-processed. Just like coffee, chocolate will go through a roasting process and that will help develop flavor, it will help to change the acidity, the bitterness, the astringentness.

A lot of chocolate makers, the roast is so key for them because the roast will define the flavor of the chocolate bar. So you could do a light roast compared to a dark roast and have a completely different taste in your chocolate bar. There’s one chocolatier up in the Northwest and that’s what he does with his chocolate. That’s kind of his thing is that he’ll do a light roast, or a dark roast, or a medium roast with the same types of chocolate beans and then he’ll put out three different chocolate bars according to how he processed each one.

For me, I’m directly sourcing all the beans from farmers. We’re getting them in from small-scale farms. It’s all certified organic, it’s all certified fair trade. There’s no type of slave labor. Most of the beans are coming from South America, not all, but most of them. We get them unprocessed. We get them unheated and unchanged. The beans will still go through a fermentation process and that’s a part of processing that needs to happen on the farm.

That’s another reason why I have a higher price on my chocolate is that a lot of the beans are more delicate, or at least a couple varieties are hand-peeled. I’m getting some from Ecuador that are all hand-peeled. So that does definitely change the deal in the chocolate.

I also do what are called “inclusions.” Anytime you see a flavor addition to a chocolate bar, it’s called an “inclusion.” What I’m doing is adding essential oils. I’m adding herbs, spices, aged balsamic vinegars, salts, whole fruits, whole fruit juices, things like that. I’m using a whole food, an herb or something like that to change the flavor.

You get beans that have nutty, coffee flavors that are grown in Mexico, near a lot of coffee plantations. You get stuff that’s really fruity and tangy like mangoes and tart types of flavors. Those might come out of Hawaii, or come out of more of a tropical jungle.

[laughter]

I’m getting better at it. I’m not perfect yet, but I can eat a bean and I know it’s from Madagascar. For some odd reason Madagascar beans have a particular dry fruit, [inaudible 14:23] flavor.

I would do four to five farmers’ markets every Summer. Even that was kind of a deal with chocolate. But as I was engaging with customers and learning about the type of product that I was selling, getting out there to the people, I realized that there was so much education that had to be involved. To open the retail space, it was something I figured was always kind of a necessary goal, to really grow the business, and to engage customers.

Initially, we opened the space because I needed a new kitchen. It was a cool space. Rent is not high for this area. As far as what’s going on in your mind, it’s one of those things where you just kind of have to pull the trigger. It’s a stressful deal, but business won’t grow unless you take those kind of risks. I knew it was just another stepping stone for growth of the business.

That’s exactly what drives them under. Unless you’re willing to change and take those risks, you’re right, you don’t actually grow.

Having this first retail space was really good to give me an idea of what are people actually looking for. What do they want to have in a retail space? What do they want to have in a chocolate shop? What kind of products are they looking for? I’m scared as hell.

[laughter]

Same with a business. This is my baby. This is my little child, that’s now running and growing. I have to figure out how to feed it and how to pay its bills.

[laughter]

They see the process every single day. They pay attention to the bills every day. They pay attention to ordering, and product coming and going. That’s really just the evolution of any business. So, I’m to a point where I’m able to take some more time, take some days off and really let it grow and flow on its own accord. Which feels better.

Now, as I’m looking for growth, what do I need to do for myself, as the owner and the chocolate maker? What type of growth is going to happen for future employees and things like that? I’m excited. Underlying all that fear, there’s always this bubbling of excitement that’s…

Maybe take us through a quick process of how you find your suppliers. You mentioned a little bit earlier that your Cacao beans come from a place. The organic farms there, free of slave labor, things like that. In general, how do you find your suppliers, and how do you pick between them?

When I met him he was sourcing from this one farm in Ecuador. He goes down there probably four or five times a year. He’s helping them change the process to become a better, healthier product. He’s teaching them how to ferment their beans differently, and how to process the beans differently.

For his exact specifications, he was also a raw chocolatier. What was really cool for me is that I’m like, “OK, everything’s done for me.” He took care of all the details about…

It was kind of nice that one of my best friends, that I studied under and learned from, was best friends with this other chocolate maker. As the world kind of turns, you realize how small it is, you know? [laughs]

As it evolved and as we would grow, I’ve met other people along the way. There’s actually a guy now, here in Utah. His product is called Crio Brü. I don’t know if you’ve seen Crio. Eric, he’s an amazing person that sources beans. I’ve worked with him to get beans. I’ve worked with other chocolate makers.

I work with a guy that runs his company in Denver, but he actually lives in Ecuador and has a farm in Ecuador. He and I have worked together, and he’s gotten me in touch with other chocolate makers and other farmers. It’s just been a matter of, now that I’m in the industry, it’s not hard. But for the first few years I was just pretty lucky, as far as it just fell in my lap.

Right now we’re able to do still small orders and small batches, because I know other chocolate makers that are buying beans. We can split the cost and share shipping cost and things like that.

I’ve seen that same principal in other businesses, so I kind of want to ask that question to you. It seems to me you’ve been able to find different chocolates, and as it’s growing, your source for chocolates has changed, therefore the taste is going to change a little bit as well.

As a chocolatier, do you find it more important to keep the chocolate taste the same, or maybe keep it the same for a while and then change it? Or continuing to change to find something better?

I love that those little nuances are there. It’s not a mass manufactured product. It’s going to taste different every single time I make it, even if I do a precise process. Now, I have figured out how to create a system. We do have system for making the chocolate. We have a system for pouring the chocolate. We have a system for cooling the chocolate.

We have a system for wrapping, packaging and labeling. All of that’s done the same. Whereas, the ingredients might have subtle changes. Right now, I’ve been using the same Cacao from Peru. I’ve been using that bean for over a year and a half now. Now the chocolate has been pretty steady.

But the honey has changed. The honey changes the consistency of the chocolate. The melt point might change because of the honey, as far as the crystallization of sugars. There’s always subtle differences, but never drastic differences anymore. I think for the first couple of years there were drastic changes. that was as far as evolving the product and making it…fine tuning the product.

Now that I fine-tuned it, and I found a product that tastes good, now there’s just little, subtle changes. Other than that, there is a system involved in the making of the product.

[laughter]

For me, that’s part of the whole experience with a gourmet chocolate: you’re not always expecting it to be the same. It’s the excitement of what type of a party’s going to be in my mouth at this point in time, you know? As long as there’s chocolate in there it’s always going to be a party. [laughs]

A couple of general questions, I suppose. We’re going to do the good and the bad here. I think it’s kind of obligatory, but I think people need to hear it as well. What’s your least favorite thing about this business or industry?

You know, 70-80 percent of my sales are done with a credit card. If I didn’t take credit cards, my business would probably go under. It’s weird that I’m totally against that. I don’t want to take credit cards. I don’t want to pay for my business license. I don’t want to, but that’s just kind of me being anti-establishment and anti-corporation. That’s just, yeah.

That’s what I love. I love my customers. I love the people that are satisfied. I love that it’s a fuel for my creative innovations. It helps clear my head. It keeps me busy in a sense that this is what I love to do. But yeah, as far as running a business, we all have our ups and downs, accounting, doing books, all that stuff.

But those are little things that are just necessary to run a business. To actually do the part that I love. The part that makes me happy and that is fruitful. It outweighs all that other stuff hand in hand. As I’m growing, I’m just finding help to get those things done. If I don’t want to do my books, I hire somebody to do my books. As a business grows and evolves, I can’t do it all. I have been, and so now I’m to the point where I’m delegating and letting people take care of things that I can’t do.

That’s I think the biggest thing. I’ve had to let my pride get out of the way, or my ego, and get out of my own way as far as producing a product and knowing that it’s a good product. Not second guessing if it’s good or not. If I need a day off, take a day off. If I need to make chocolate, I make chocolate.

I think one of the biggest things is being my own boss. I’m the manager, owner, chocolate maker of this company. But I’m also my own boss now. I have to really be responsible on the days that I need to be responsible. As of doing that so much then I hit a point where I just want to be reckless [laughs] and irresponsible.

I’ll take a few months of being very responsible and very key on what I need to get done. Then I’ll take a few months during the summer just to be reckless and sleep in and have some good times with my friends in the nights. Then I’m realize, “OK, back to work.” Now the holidays are kicking in. I’ll be busy again.

I’m learning that flux, but that’s also just a way to keep me sane as well. If I was always responsible, I would lose it over a while. If I were always reckless, I would lose it over a while. It’s just finding that balance.

I think the biggest thing to overcome is balance, and that’s with any business owner. I think trying to balance family time or a relationship or just your own life. Finding time to eat and sleep. [laughs] Balance is kind of really what’s been a big challenge for me.

[laughter]

But if it’s one of those days I don’t have things organized, it’ll all just fall to the ground. I think the biggest thing I’ve learned over the past few years is developing those systems for people that need it, so I don’t have to be involved as much.

But I’m like, “Hey, this is what I have to do for the summer. I don’t have proper AC. I’m not going to send you a bad product. I’m not going to send you a product that isn’t going to look good when one of your customers opens it.”

It’s hard to do that. It’s hard to say, “Sorry, we’ll get you chocolate in two weeks.” [laughs] But it’s what I want to do with my company. I don’t want to send out a bad product. I don’t want to just for the sales. With chocolate, the profit margins are so low with what I’m doing with the specialty product. I think I have to be very discerning when it comes to getting chocolate in the store.

I’m not doing this to make a dollar. I’m using high quality ingredients. The best I can find. We don’t cut corners. I don’t look for cheap, West African cacao that’s 20 cents a pound. [laughs]

I’m buying chocolate that’s $10 a pound or $5 a pound depending on where it comes from and making sure that it’s organic, making sure that the ingredients are raw. If I can’t find an ingredient, I don’t do a substitute. I don’t find something that’s just a cheap filler. We wait. We give it two months until we can actually find that ingredient.

That’s been an issue as far as customers, as far as keeping them satisfied with the same product over and over. But if it doesn’t meet the standards of my business, then we don’t do it.

It’s such a first impression type of thing. People don’t lie when they say first impressions are important. For a chocolate bar, a first impression has to be a good one. My product has grown and evolved, and I know people who used to eat it three, four years ago but they didn’t necessarily like it. Now they’re like, “Wow, your chocolate’s changed. It’s better.” That’s what I want…

[laughter]

The quality control will have to fall on the employees. They’ll have to know the discerning qualities that I’m looking for. Because I’ll taste a product and I’ll be like, “Mm, yeah, no.” But they’ll be like, “Oh, it tastes OK.” And I’m like, “Yeah, but it doesn’t taste amazing.” I think over time, that just will come with me training my employees to look at the discerning qualities of if a product can go out or if it can’t go out.

Yet, the pressure of shipping something gets to them, and so they ship it anyway. I don’t know if you’ve had to change your mindset. Or have you always had that mindset? Or how do you think people could go about changing?

But she really wanted it for some family barbecue thing. She lives in Pittsburgh or Philadelphia or I don’t even remember. We end up shipping product. I did what I could as far as insulation and wrapping the product and using dry ice and doing overnight shipping.

She paid overnight shipping on this product, and it gets there and it still isn’t frozen. There were a couple that had thawed out. The packaging that we had shipped it in, the ice cream had absorbed some of the packaging flavor.

This customer was very upset, and I’m like, “Look, I told you that all of these things that could have happened and why I didn’t ship my products.” But she was very insistent, and I should have just told her no.

I dealt with the headache. I dealt with all the stress of “Is it going to ship?” I have to go back and forth to the post office to get packaging, and I have to deal with getting the dry ice and making sure the time goes out in a timely manner. I pulled up all this stress when really I should have just said, “Nope.” [laughs]

From having that one experience that was strong enough to make me remember, then now, when it comes up and people ask, I just say no. I think it’s a learning process. You have to have that one experience to make you remember to not say yes again. I’ve had a few things like that happen in my business. Once you make a mistake, you never make the same one.

Right now, just kind of as an idea, I’m working with another company to develop a new product. We have to look at where are we sourcing the ingredients? How much ingredients are we going to be using? What’s the packaging going to look like? What’s the cost of the packaging?

How can we distribute this product? How are we going to get it on the market? What entities have to certify the product? What companies have to inspect the product, like the Department of Food and Ag or the health department? How much times is this going to take to actually produce in a week?

Those are just some of the details. But as far as developing a business, you have to look at what business license am I going to get? How am I going to set up my business? How am I getting funding? How am I going to do startup costs? What’s my product that I’m going to sell, or what is my business selling? You want to look at a business as a product. What am I going to be representing?

Really take the time to lay a good foundation and have a plan. 90 percent of businesses don’t have a plan. Everyone says make a business plan and have a business plan, and it’s kind of like, “Yeah, I just have an idea.” Really do have a functional plan that is written down. When you take a goal and you actually write it on paper.

It becomes much more of an imprint that’s going to turn into a reality. I think that goes the same for business. I think the more you write things down, the more you have set ideas, goals. Really get those things in place, and know your strengths and know your weaknesses. Let go of the pride when it comes to your weaknesses, and be able to admit those weaknesses and say, “I’m not good at this. I need to find somebody that is.”

That’s really what I’ve learned from running the business, is just to get out of my own way and to really make sure that the people who I’m working with they’re doing a good job as well, and they know what they’re doing also. Take the time to find that right person.

Right now, I’m looking for somebody to manage my business. I want somebody who’s health minded, somebody who eats well. Someone who understands the chocolate industry. This person has a lot of qualities, and it’ll come to me eventually.

But it’s hard to find that person who may be out of a job or may not be doing anything who has time to take on running a chocolate company. So it’s kind of like, “All right. I guess all things in good time.”

But again, take your time with everything. Don’t rush into it. Allow your business to grow slowly. I know a lot of businesses that grow too fast too quick. They get overwhelmed. They don’t know how to keep up with production. They don’t know how to keep up with small equipment. So really look towards growth, but also take that growth in stride. Take it in its own time. Allow it to grow organically and functionally without losing your mind.

Give yourself some time. Right now, just buy a Jeep Wrangler, something like that. Just buy a mid-grade vehicle right now to get you to the point where you need to. Then buy a really nice car. That’s really what it comes down to with equipment. But find stuff that’s functional and can match your manufacturing processes.

Hop on the website. The website is www.eatchocolateconspiracy.com. We do ship during the winter, so come October we’ll be back up and running online. You can find us at specialty shops outside of Utah as well. If you’re traveling or if you know people in the area. We sell into Seattle, LA, San Diego, New York, Brooklyn, Kansas City, Ohio.

There’s a few places like that that sell our chocolate. A few online retailers that sell it as well. We’re slowly growing and getting out there. Harmons is interested. So is Whole Foods. We’ve just been biding our time with them, but eventually you’ll see our product in Harmons before you will Whole Foods.

So that’s the next big jump as far as distribution. When Harmons picks it up, all their stores will pick it up. I think they have 16 stores in Utah, so they’ll all pick it up at once. So yeah, you’ll see us do a big jump of growth eventually.

[laughter]

I connected with them I have been working with them now for the past year. They’re great. they have been getting me into new stores again they work with your growth. They’re not pushing make as a chocolate maker to distribute more. They’re allowing me to grow in my own time and when I’m ready they will make the contacts to Whole Foods or the Harmons. But they’re a great company to work with. They alleviate a lot of stress and so…

I was like oh great that is my distributor he was like cool I will just order it from them. He did not have to deal with ordering from me or anything like that i dropped the product off. I sold him on the product, and then the next thing I knew an order went through for A Priori. Now he carries my chocolate.

So a new store in San Francisco, and I don’t have to do much work as far as keeping up with him and keeping up the customer base. They take care of that. “Hey, where’s your stock on Chocolate Conspiracy? Are you pleased with the product?” Blah-blah-blah-blah-blah. So they do a good representation as far as sales for my product, and it alleviates a lot of stress for me.

That’s been really key. It’s been really nice having someone just do the legwork because it’s hard to keep up with stores. It’s hard to keep up with emails. It’s hard to check in all the time and see how the product’s doing. When I get involved in the kitchen, I don’t have time, and it’s nice to have someone who I know is doing that for me.

Hi Chris, Grandma here. Good site you have here, I love it!